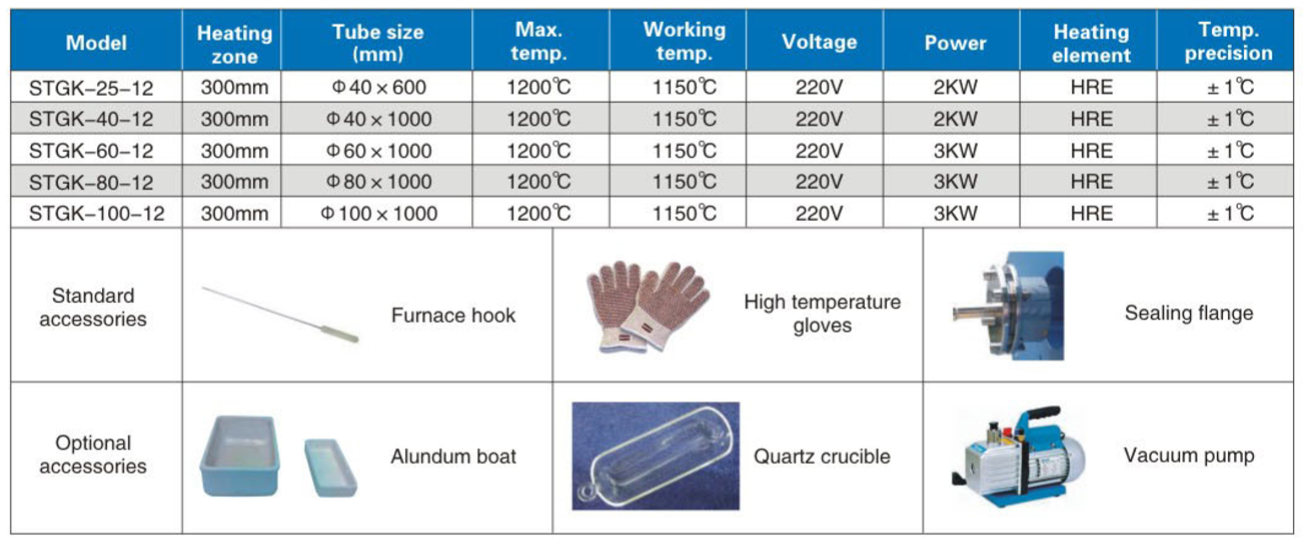

1200℃ Vacuum Atmosphere Split Tube Furnace, Tube Size Φ 80x1000, Power 3KW, STGK-80-12, Sante Furnace

- Brand:Sante Furnace

- Model:MO00990033

- Availability:In Stock

Description PDF

Split Tube Furnace.pdf (1,222 KB)

Split Tube Furnace.pdf (1,222 KB)

Ask Question About Product

Brief introduction:

1 Max 1200°C design, continuous operating at 1100°C.

2 High-quality alloy resistance wire as the heating element

3 High-quality Alumina Ceramic Fiber as chamber material

4 Temperature controllers: PID temperature control, LCD touch screen can choose.

5 Quartz Tube size: Φ10mm-500mm

6 Thermocouple: K style

7 Application: Laboratories of institutions of higher learning. Scientific research institutions factory enterprise. New material field (metal material, ceramic material, nanomaterial, semiconductor material etc.)

Product description

STGK series products mainly aim at the laboratory samples’ heat treatment under vacuum or protective atmosphere with high-quality chamber material and stable temperature control system, which can ensure the reliability of experimental data. New type ceramic fiber material as the chamber material, high-quality high-temperature alloy wire as heating element. Both ends of the tube have stainless steel flange sealing for easily and conveniently disassembling. Temperature controller adopts large touchscreen microcomputer with PID control module, which can reach accurate temperature control and constant temperature requirements.

Product features

1. Chamber material adopts mullite ceramic fiber, which keeps it without transformation under high temperature, small heat capacity and saving energy more than 50%

2. Heating element adopts high-temperature alloy wire which can bear heavy load. It is stable and has a long service life.

3.Quartz tube with stainless steel flange sealing on both ends. It is not only simple and reasonable design and easily disassembling, but also conveniently for sintering samples in and out.

4.Fast heating speed. It takes 15-30 minutes from room temperature to 1000℃

5.High precision of temperature control with the temperature compensation and correction function at precision±1℃

6. Temperature control instrument has programmable function and it can set heating curve and programme 30 segments.

7. Integrative structure: Furnace body can be open and closed to observe samples in the tube

8. Electronic parts and components adopt DELIXI brand with earth leakage function. It is safe and reliable

9.Over-temperature alarm function. It will send out sound and light alarm and stop heating when the temperature exceeds the desired temperature.

10. The optional large screen paperless recorder can complete the real-time record of the heating curve with memory card to analysis and print experimental data.

11. With optional gas mass flow meter and inlet gas with digital accuracy control.

-200x200.jpg)