D3024 High Speed/High Speed Refrigerated Micro Centrifuge 200-15000rpm,DLAB

- Brand:DLAB

- Model:D3024

- Availability:In Stock

Description PDF

D3024 Series Centrifuge.pdf (216 KB)

D3024 Series Centrifuge.pdf (216 KB) User Manual_D3024 _ D3024R.pdf (799 KB)

User Manual_D3024 _ D3024R.pdf (799 KB)

Ask Question About Product

Note D0324R has been discontinued, and it is replaced by D1524R.

Description:

High Speed Refrigerated Micro-Centrifuge,with AS24-2 aluminum alloy rotor kit 19400006 (package contain in the box)

High Speed Micro Centrifuge

High speed micro centrifuges are widely used in physical and chemical analysis, biochemistry, cellular and molecular biology, clinical Labs ideal for high-end research applications.

• Sedimentation of cells and viruses

• Separation of sub-cellular organelles

• Isolation of macromolecules such as DNA, RNA, proteins or lipids

Precise control

• Brushless DC motor accelerates quickly to the set speed

• High accuracy of speed in ±20 rpm

• Digital timer adjustable from 30 sec. to 99 min or set for continuous run

• Timer starts only when the set speed is achieved and then maintains the accuracy of separation time.

Conforms to international safety standards and regulations

• DLAB centrifuges passed CE, cTUVus and FCC requirements, certifications, they are certified by TUV. All DLAB test items are proven with the high level of reliability and confidence according to IEC/ EN 61010-1, and pass MCA test according to IEC/EN61010-2-20, including explosion-proof and bio-safe tests.

• Quiet operation, maximum reliability

• High strength metal casing ensures security during centrifugal process

• Dual door interlock design for safety (D3024 & D3024R)

• Gentle braking at low speed with efficient separation

Ergonomic design

• User-friendly large LCD display shows real-time information

• Both RPM or G-force can be set and displayed

• The parameters can be modified after the set speed is reached.

• The short spin function is used for quick spins by pressing and holding PULSE key. The centrifuge speed can be accelerated and held at the target speed

• Automatic lid-lock release prevents sample warming and allows easy access (excluding D3024R)

• Concise display and Sound-alert

Powerful cooling system for precise temperature control

• Pre-cooling program ensures optimal protection of the sample before warming

• Guaranteed 2°C cooling within only 7 minutes of both chamber and samples even at maximum speed and capacity utilization

• Sound-alert allows your undivided attention on other tasks warming

• Lid lock facility allows for internal temperature maintenance even after centrifugation

• Intermittent temperature control mode, CFC-free refrigerant and low carbon life rotor capacity

• Bio-safe rotor/anti-sample overflow prevents accidental leakage during centrifugal process allowing risk-free microbial contamination

• High strength aluminium alloy rotor can be fully autoclaved for unlimited service life

• Four rotors are optional complete with 24 place 1.5/2.0mL tubes, bigger 5.0mL, smaller 0.2mL and 0.5mL tubes with the use of adapters

• Quiet running, noise level ≤ 54dB

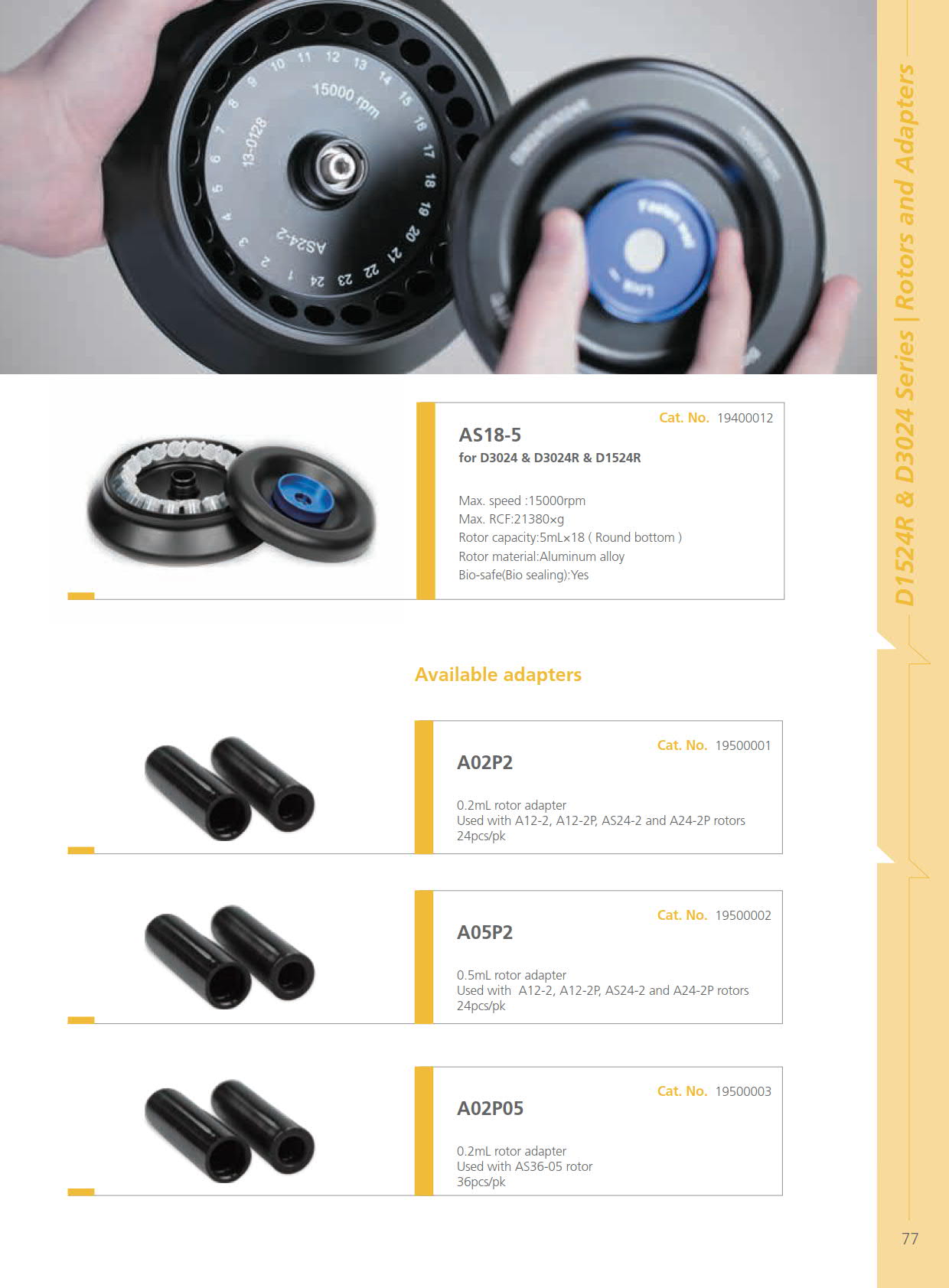

Rotor Features:

DLAB rotors are manufactured from military-industrial grade aluminium alloy with high mechanical strength for precise running and safety (excludes D2012 plus rotor).

• Every rotor can reach a maximum speed of 15000rpm

• Rotors are seated on a tapered shaft, concentric and self-aligning, perfect to achieve running stability at high speeds

• D3024 & D3024R with bio-safe rotors/ anti- sample overflow prevents accidental leakage and risk free centrifugal process microbial contamination.

• D3024 & D3024R rotors have passed MCA test according to IEC/EN61010-2-20, including explosion proof and bio-safe tests

• High strength aluminium alloy rotors are fully autoclavable and provide unlimited service life (D2012 plus rotor not included).

• Powerful cooling system minimizes rotor heating. D3024 rotors heat up to > 10°C and D2012 rotors less than 8 °C after running an hour.

Fully autoclavable

High strength aluminium alloy rotors are fully autoclavable, withstanding steam sterilizing at 121°C for 20 minutes, with unlimited service life.

Bio-safe

Aspired to be the top-of-the-line model, D3024 & D3024R rotors are designed to prevent sample leakage. Each and every rotor is hermetically sealed by three rubber seals.

Explosion-proof

DLAB centrifuges are constructed under MCA conditions according to IEC/ EN61010-2-20, causing disruption by partially cutting and overloading rotor assembly, and guarantee that no part shall be detached to cause danger to person or the environment.

Specifications:

|

Specifications |

D3024 |

D3024R |

|

|

Max. Speed |

15000rpm(200-15000rpm), increment:10rpm |

15000rpm(200-15000rpm), increment:10rpm |

|

|

Max. RCF |

21380×g, increment:10×g |

21380×g, increment:10×g |

|

|

Speed Accuracy |

±20 rpm |

±20 rpm |

|

|

Temperature Range |

---- |

-20~40℃ |

|

|

Rotor Capacity |

5mL×18, 5mL culture tubex12 0.2mL/0.5mL/1.5mL/ 2mL×24, |

5mL×18, 5mL culture tubex12 0.2mL/0.5mL/1.5mL/ 2mL×24, |

|

|

Run Time |

30sec-99min/Continuous |

30sec-99min/Continuous |

|

|

Motor |

Brushless DC moto |

Brushless DC moto |

|

|

Safety Devices |

Dual door interlock, Over-speed detection, |

Dual door interlock, Over-speed detection, |

|

|

Power |

Single-phase,AC220V-240V, 50Hz/60Hz, 5A, AC110V-120V, 50Hz/60Hz, 8A 200W |

Single-phase,AC220V-240V, 50Hz/60Hz, 5A, AC110V-120V, 50Hz/60Hz, 8A 200W |

|

|

Acceleration |

25s↑25s↓ |

25s↑25s↓ |

|

|

Dimension [D×W×H] |

280×364×266mm |

280×364×266mm |

|

|

Weight |

12kg |

12kg |

|

|

Certification |

CE cTÜVus FCC MCA |

CE cTÜVus FCC MCA |

|

|

Advanced Features |

Speed/RCF switch; Short-time run function; sound-alert function |

Speed/RCF switch; Short-time run function; sound-alert function |

|

|

Noise Level |

≦64dB |

≦56dB |

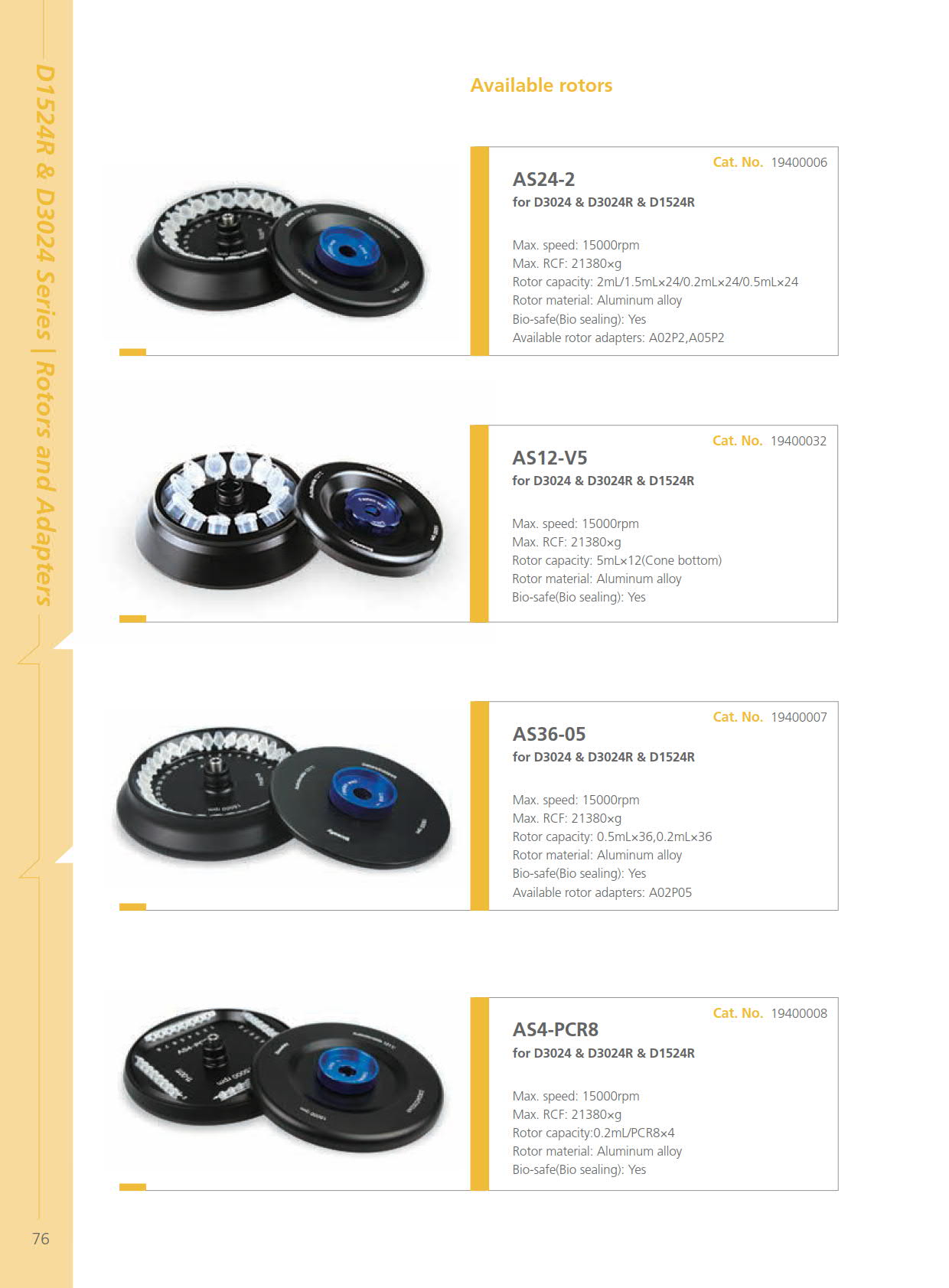

| Accessories of D3024 Series | |||

| Cat. No. | P/N | Descriptions | |

| 19400073 | AS18-5 | Aluminum alloy rotor kit with lid (blank LOGO), fixing clips and O'ring, 15000rpm, 5ml*18, used with D3024 & D1524R(eppendorf round tube) | |

| 19400070 | AS12-5V | Aluminum alloy rotor kit with lid (blank LOGO), fixing clips and O'ring, 15000rpm, 5ml*12(eppendorf cone tube), used with D3024 & D1524R | |

| 19400069 | AS24-2 | Aluminum alloy rotor kit with lid (blank LOGO), fixing clips and O'ring, 15000rpm, 2ml/1.5ml*24, used with D3024 & D1524R | |

| 19400071 | AS36-05 | Aluminum alloy rotor kit with lid (blank LOGO), fixing clips and O'ring, 15000rpm, 0.5ml*36, used with D3024 & D1524R | |

| 19400072 | AS4-PCR8 | Aluminum alloy rotor kit with lid (blank LOGO), fixing clips and O'ring, 15000rpm, 4*PCR8, used with D3024 & D1524R | |

| 19500001 | A02P2 | 2ml to 0.2ml rotor adapter, used with A12-2, A12-2P, AS24-2 and A24-2P rotors,24pcs/pk | |

| 19500002 | A05P2 | 2ml to 0.5ml rotor adapter, used with A12-2, A12-2P, AS24-2 and A24-2P rotors,24pcs/pk | |

| 19500003 | A02P05 | 0.5ml to 0.2ml rotor adapter, used with AS36-05 rotor,36pcs/pk | |

DLAB rotors are manufactured from military-industrial grade aluminum alloy with high mechanical strength for precise running and safety (excludes D2012 plus rotor)

Every rotor can reach a max. speed of 15000rpm

Rotors are seated on a tapered shaft, concentric and self-aligning, perfect to achieve running stability at high speeds

D3024 & D3024R with bio-safety rotors/ anti- sample overflow prevents accidental leakage and risk free centrifugal process

Microbial contamination. D3024 & D3024R rotors have passed MCA test according to IEC/EN61010-2-20, including mechanical safety and bio-safety tests

High strength aluminum alloy rotors are fully autoclavable and provide unlimited service life (D2012 plus rotor not included)

Powerful cooling system minimizes rotor heating. D3024 rotors heat up to > 10°C and D2012 rotors less than 8℃ after running an hour

Rotor Features

Fully autoclavable

High strength aluminum alloy rotors are fully autoclavable, withstanding steam sterilizing at 121°C for 20 minutes, with unlimited service life.

Bio-safety

Aspired to be the top-of-the-line model, D3024 & D3024R rotors are designed to prevent sample leakage. Each and every rotor is hermetically sealed by three rubber seals.

Mechanical safety

DLAB centrifuges are constructed under MCA conditions according to IEC/EN61010-2-20, causing disruption by partially cutting and overloading rotor assembly, and guarantee that no part shall be detached to cause danger to person or the environment.

.jpg)

-200x200.jpg)

-310x310.jpg)

-310x310.jpg)

-310x310.jpg)

-310x310.jpg)