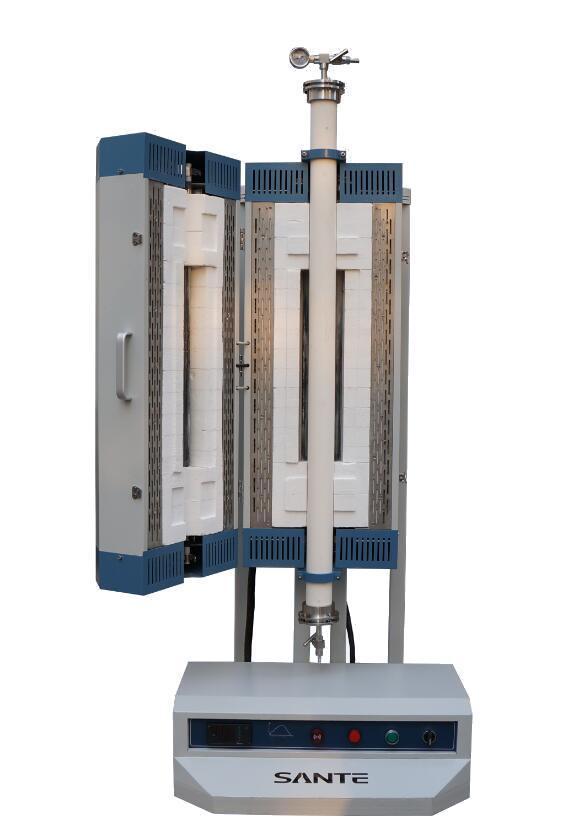

1200℃ Vertical Split Tube Furnace, Tube Size Φ 80x1000, Power 3KW, STGL-80-12, Sante Furnace

- Brand:Sante Furnace

- Model:MO00990037

- Availability:In Stock

Description PDF

Split Tube Furnace.pdf (1,222 KB)

Split Tube Furnace.pdf (1,222 KB)

Ask Question About Product

Brief introduction:

1 Temperature according to customer request

2 High-quality alloy resistance wire as heating element

3 High-quality Alumina Ceramic Fiber as chamber material

4 Temperature controllers: PID temperature control, LCD touch screen can choose.

5 Alundum Tube size: Φ10mm-150mm

6 Thermocouple: S style

7 Application: Laboratories of institutions of higher learning. Scientific research institutions factory enterprise. New material field (metal material, ceramic material, nanomaterial, semiconductor material etc.)

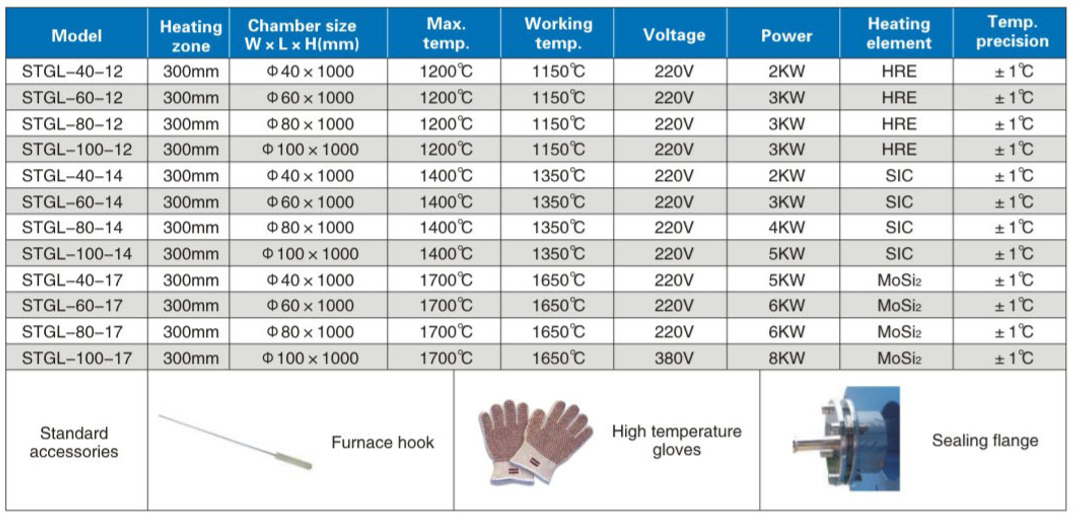

Parameters

I Sintering Performances:

1.Tube Size mm): Φ40mm×1000mm Φ60mm×1000mm Φ80mm×1000mm

Φ100mm×1000mm

2. Heating Area Size: 440mm

3.Constant Zone Size: 300mm

4. Rated Max. Temperature: 1200℃

5.Long-term Working Temperature:1100℃

6.Temperature Stability: ±1℃

7.Heating Speed: 1-20℃/min

8.Chamber Material: Imported High Purity Alumina Ceramic Fiber

9.Thermal Insulation Material: Polycrystalline Mullite Ceramic Fiber Material

10.Tube Material: Quartz tube

II Heating Control Performances:

1.Voltage:220V

2.Heating Power:4KW

3.Heating Element: High-temperature alloy resistance wire

4.Control Mode: It adopts imported intelligent microcomputer temperature control instrument with PID parameter self-tuning function and manual-automatic switch with non- interference function, over-temperature alarm function and can programme 2 groups 16 segments. Also, it has automatic heating, automatic insulation and automatic stop functions which can meet the requirements of temperature control and constant temperature.

III Other Performances:

1. Furnace Structure: Integrative structure, double shell, air circulation heat insulation

2. Temperature measurement: S platinum-rhodium thermocouple

3. The chamber adopts high-quality alumina ceramic fiber and the resistance wires are arranged on the two sides of the chamber with good temperature uniformity and it is sturdy and durable.

4. With alerting signal for the over-temperature during the working process and it can complete protective action automatically.

5. When programs are set and press the starting-button, the following steps will proceed automatically.

6. The shell adopts high-quality Shanghai Baogang cold-roll steel sheets with dusting surface and electrostatic spraying.

7. Sealing property: Both ends with stainless steel metal flange sealing and matched with high-temperature PTFE gasket making sintering under the vacuum and vacuum at degree -0.1Mpa. Both sides of flange have gas inlet and outlet port with pressure gauge is installed on the metal flange. Stainless steel precision needle valve can adjust flow rate and can inlet protective gas.

-200x200.jpg)