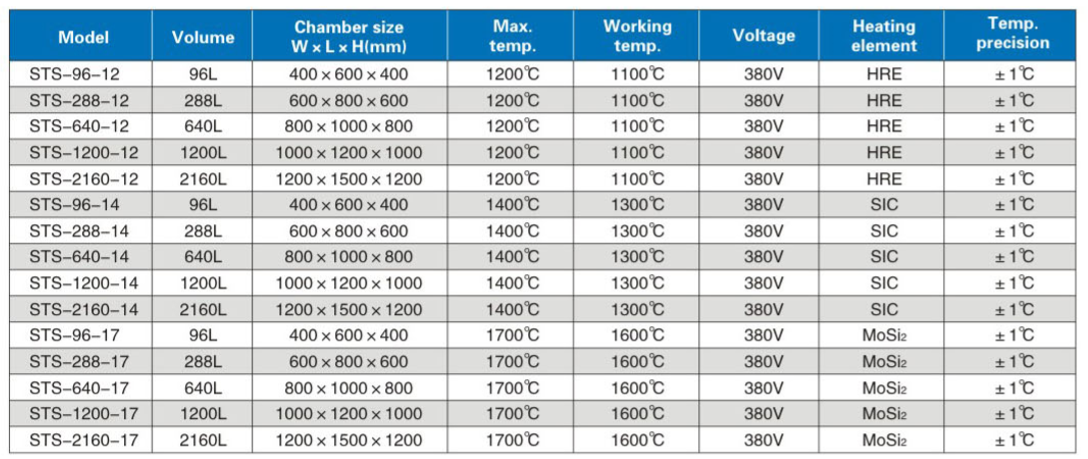

1200℃ Elevating /Lifting Sintering Furnace, Volume 1200L, Chamber Size 1000x1200x1000, STS-1200-12, Sante Furnace

- Brand:Sante Furnace

- Model:MO00990105

- Availability:In Stock

Description PDF

Lifting Sintering Furnace.pdf (669 KB)

Lifting Sintering Furnace.pdf (669 KB)

Ask Question About Product

Brief introduction:

1 Temperature design up to 1700°C, can be done according to customer OEM request.

2 High-quality MoSi2 Rod as heating element

3 High-quality Alumina Ceramic Fiber as chamber material

4 Temperature controllers: PID temperature control, LCD touch screen can choose.

5 Chamber size: 60Liters-2100 liters, according to OEM request

6 Thermocouple: B style

7 Application: Laboratories of institutions of higher learning.Scientific research institutions factory enterprise. New material field (metal material, ceramic material, nanomaterial, semiconductor material etc.)

Product features

1. High purity alumina ceramic fiber as chamber material with no powder drops off in high temperature and with the advantage of small heating capacity and saving energy more than 50%.

2. The imported temperature control instrument with high precision of temperature control and has the temperature compensation and correction function at precision ±1℃

3. PID temperature control instrument with program function. Heating curve can be set with program for 16 groups and 30 segments per group.

4. Electronic parts and components all adopt DELIXI brand with earth leakage function and it is safe and reliable.

5. Elevating furnace chamber with four side heating and temperature uniformity is excellent, which is especially fit for the high-grade sintering process with this request.

6. With alerting signal for the over-temperature function. It will send out alarming signal and stopping heating when the over temperature happened.

7. Elevator furnace is made up of chamber, temperature control system, furnace bottom lift and furnace bottom mobile system. The chamber and the temperature control system are separated design with independent temperature control box and clear control panel. Furnace bottom trolley lifting, furnace bottom and chamber with coupling sealing and can stop automatically. The switch button is integrated into the temperature control cabinet panel and it is beautiful and easy to operate.

8. Optional installation of gas inlet pipe is available and it can inlet inert gas for purging and protecting. Also, it can install exhaust chimney, connecting with stainless steel bellows to make the high temperature volatile and harmful gases flow to the specified place.

-200x200.jpg)