1200℃ Car Bottom Sintering Furnace, Volume 640L, Chamber Size 800x1000x800, STT-640-12, Sante Furnace

- Brand:Sante Furnace

- Model:MO00990119

- Availability:In Stock

Description PDF

Car Bottom Furnace.pdf (1,851 KB)

Car Bottom Furnace.pdf (1,851 KB)

Ask Question About Product

Brief introduction:

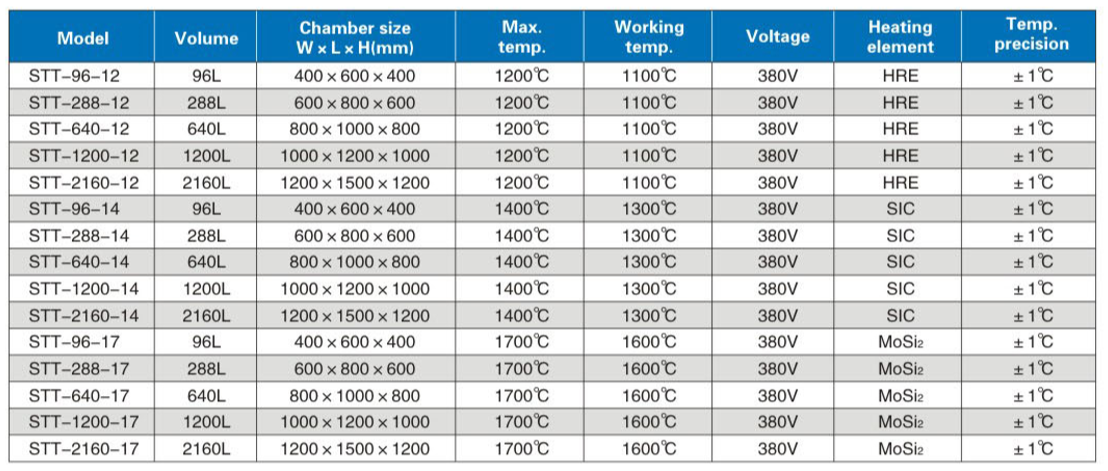

1 Temperature design up to 1700°C, can be done according to customer OEM request.

2 High-quality MoSi2 Rod as heating element

3 High-quality Alumina Ceramic Fiber as chamber material

4 Temperature controllers: PID temperature control, LCD touch screen can choose.

5 Chamber size: 96Liters-2100 liter, according to OEM request

6 Thermocouple: B style

7 Application: Laboratories of institutions of higher learning. Scientific research institutions factory enterprise. New material field (metal material, ceramic material, nanomaterial, semiconductor material etc.)

Product features

1.High purity alumina ceramic fiber as chamber material with new assembling structure.No deformation and collapse at high temperature.

2. The temperature control instrument with high precision of temperature control and has the temperature compensation and correction function at precision ±1℃

3. The imported temperature control instrument with program function. The heating curve can be set with program for 16 groups and 30 segments per group.

4. Electronic parts and components all adopt DELIXI brand with earth leakage function and it is safe and reliable.

5. With alerting signal for the over-temperature function. It will send out alarming signal and stopping heating when the over temperature happened.

6. Car bottom furnace mainly consists of chamber, temperature control system, furnace door lifting system and car trolley walking system. The product is separated bodies design of chamber and temperature control system with individual temperature control box and its operating interface is placed in order and clearly. The chamber door with electric lifting system and electronic car trolley go in & out furnace easily. The car trolley and chamber is placed by coupling seal and will be stopped at its designated location. Switching push-button is integrated on the panel of the temperature control box for exquisite appearance and easily operating.

-200x200.jpg)