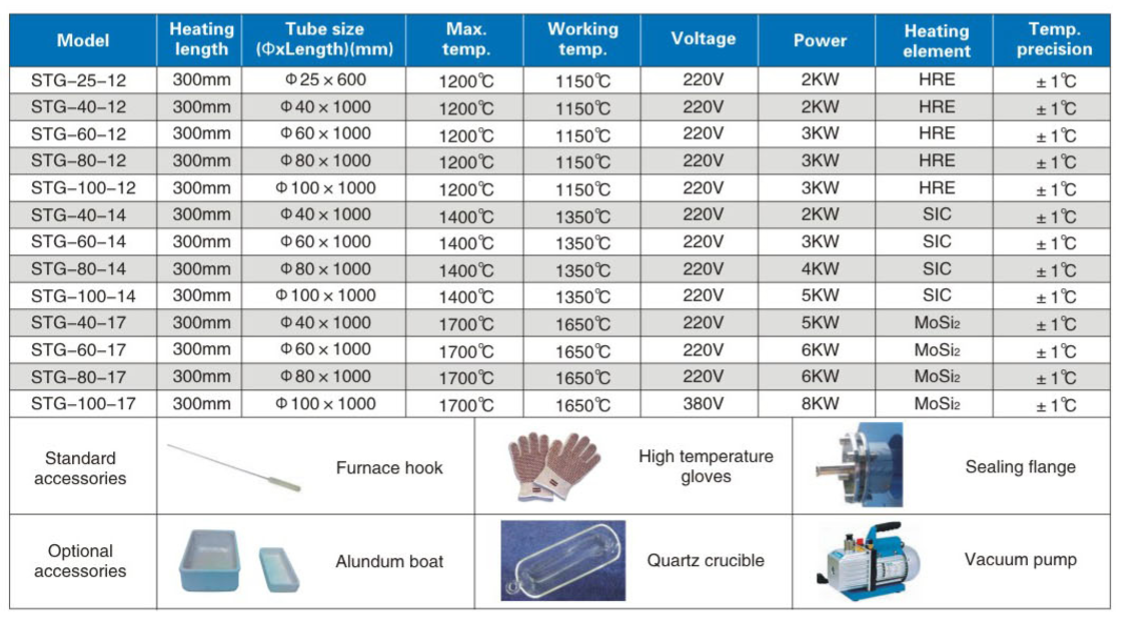

1700℃ Vacuum Atmosphere Tube Furnace, Tube Size Φ 100x1000, Power 8KW, STG-1000-17, Sante Furnace

- Brand:Sante Furnace

- Model:MO00990029

- Availability:In Stock

Description PDF

Vacuum Atmosphere Tube Furnace.pdf (1,226 KB)

Vacuum Atmosphere Tube Furnace.pdf (1,226 KB)

Ask Question About Product

Brief introduction:

1 Max 1700°C design, continuous operating at 1600°C.

2 High-quality MoSi2 Rod as heating element

3 High-quality Alumina Ceramic Fiber as chamber material

4 Temperature controllers: PID temperature control, LCD touch screen can choose.

5 Alundum Tube size: Φ10mm-150mm

6 Thermocouple: B style

7 Application: Laboratories of institutions of higher learning. Scientific research institutions factory enterprise. New material field (metal material, ceramic material, nanomaterial, semiconductor material etc.)

Product description

1600-1700℃STG series products mainly provide the heat treatment of samples under vacuum or protective atmosphere. They use high-quality chamber material and stable temperature control system and this can ensure the reliability of experimental data. New type ceramic fiber material as the chamber material and high-quality MoSi2 Rod as heating element. Both ends of the tube have a stainless steel flange sealing for working under the vacuum atmosphere. There are air inlet and outlet on the flange and it can inlet protective gas. The stainless steel flange with fast open design and it is convenient for material in and out. Temperature controller adopts large touchscreen microcomputer PID control module and can reach accurate temperature control and constant temperature requirements.

Product features

1. Chamber material adopts imported high purity alumina ceramic fiber with high hardness. It has high-temperature sintering no volatilization, environmental and safe and in line with international industry standard.

2. Heating element adopts high-quality MoSi2 Rod and bears heavy load. It is stable and long service life.MoSi2 Rods are arranged on the two sides of the chamber the furnace temperature uniformity is good.

3.Patent temperature control design with fast heating speed and good temperature uniformity. It takes 60 minutes to reach 1600℃and the sintering efficiency is 3 times compared with the same specification furnace in the industry.

4. High precision of temperature control and it has the temperature compensation and correction function with precision±1℃

5.Imported temperature control instrument with programmable function. It can set heating curve and programme 2 groups 16 segments.

6.Integrative structure with double layer shell for air circulation and heat insulation. It has excellent appearance design.

7. Electronic parts and components adopt DELIXI brand with earth leakage function. It is safe and reliable

8. With alerting signal for the over-temperature during the working process and it can complete protective action automatically.

9. When programs are set and pressed the starting button, the following steps will proceed automatically.

10. Optional large screen paperless recorder or RS232 communication interface is available. It can complete the real-time record of the heating curve and analysis and print experimental data with memory card.

-200x200.jpg)